Development of ball burnishing tool with constant force control

Development of ball burnishing tool with constant force control

Surface enhancement is one of the most important methods to improve the product performance by improving the surface properties. After the conventional machining processes, the workpiece is usually processed by thermal treatment or shot peening to increase the surface hardness and fatigue strength. However, such treatments need special equipment and additional post process, which are not usually available in most work plants. Burnish processing is a cold work process that employs plastic deformation of a surface layer in order to improve surface characteristics, such as surface finish and surface properties. It could not only reduce the surface roughness, but also increase the surface hardness, fatigue strength and wear resistance of a workpiece.

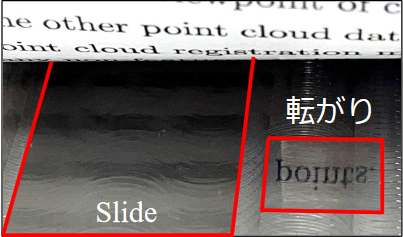

There are many factors that affect the properties of the burnished surface. The most important factor among them is the burnishing force. In the conventional burnish tool, the burnish ball is usually pressed by a spring embedded in the burnish tool. And the burnishing force is controlled by adjusting the pre-load of the spring. However, due to the characteristic of the spring and the shape of the treated surface, the burnishing force may not be stable during the whole burnishing process, which results a non-uniform modified surface.

In this research, we focus on the constant force control during the burnishing process, a ball-burnishing tool, in which the burning force can be controlled in process, was proposed. The objective of the research is to realize the generation of uniformly distributed modified layer by burnishing process with constant force control.

In the conventional burnishing process, the burnishing force should be preset before the process starts. By using the on machine force control system developed in this research, the burnishing force can be adjusted continuously during the process. By this means, it will be possible to process the complex surface, such as freeform surface, by compensating the burnishing force according to the features of the local surface. We are also concentrating on developing the force compensation method for burnish processing of freeform surface.